K Trade Fair 2019

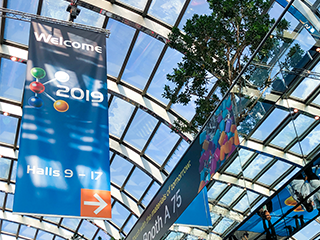

The largest in the world exhibitions will be grandly debuted on October 16-23, 2019 in German Dusseldorf. In addition to materials and materials, the latest trends and technological developments in the rubber and plastics industry. There are four main topics in this show

Industry 4.0

Core task of the plastics and rubber industrycore task of the plastics and rubber industry

Sustainable DEV.

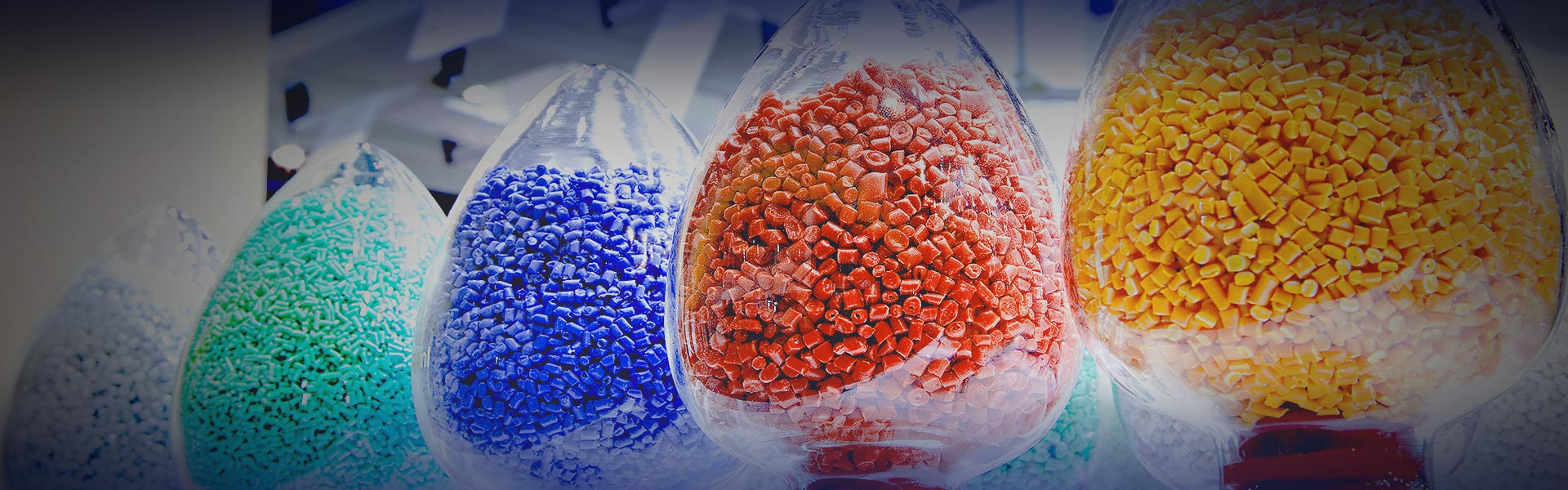

Recycling plastics、Circular Economy、Environment、Material with added value

Systems Integration

Bioplastic、Lightweight Engineering、Energy efficiency、3D printing、E-mobility

Young Professionals

Why the next generation of qualified employees is critical to the plastics industry?

2019 K Trade Fair Show Daily

2019 K Trade Fair Show Daily_1

Dear all, the once every three-year K Trade Fair is beginning now!

Today we would like to introduce plastics recycling machines company "EREMA" which is from Austria.

EREMA will demonstrate a new digital platform "BluPort" in this K Trade Fair 2019. This platform

involve cutting-edge technology. It will integrate spare parts online, investment calculator and key

performance indicators in one machine.

By the way, you can discover and experiment "BluPort" in the exhibition!

2019 K Trade Fair Show Daily_2

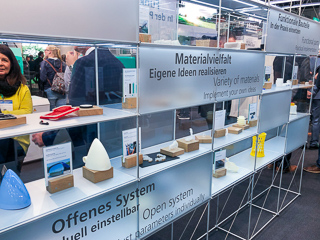

As a leader of plastic injection molding, "ARBURG" primary demonstrate topics during the K trade fair 2019 is "arburgGREENworld". "ARBURG" is exhibiting innovations in its digital product and services offering, such as the filling assistant and the plasticizing assistant, as well as the enhanced connectivity of the ALLROUNDER.

2019 K Trade Fair Show Daily_4

KUKA's major project is dedicated to industrial automation intelligence, plastic industry products and expertise at this K Trade Fair. KUKA still offer KUKA.IconProg to other manufacturers, and make sure the programming of the robot is more intuitive compared to the past. Interestingly, everyone can get a set of environmentally tableware in KUKA's booth which is made by "KUKA Flexobot"!

2019 K Trade Fair Show Daily_5

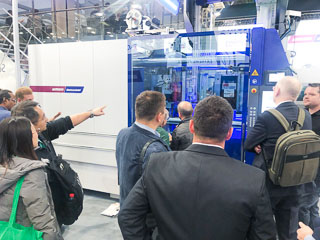

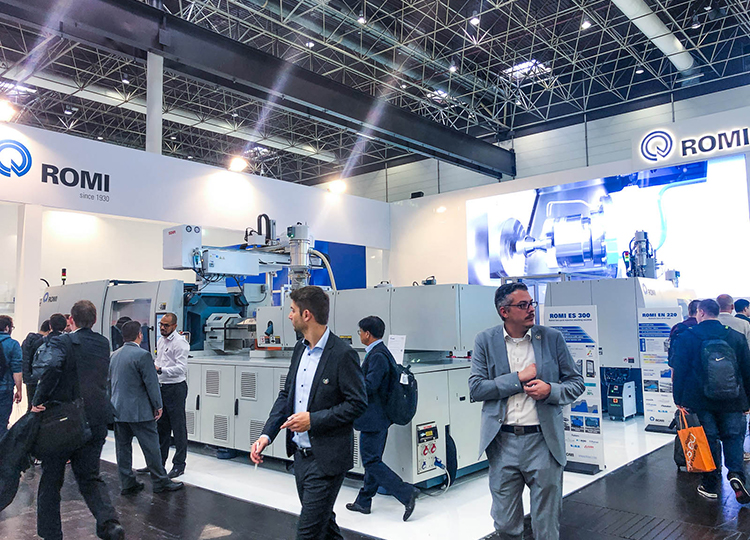

As we can see, this K Trade Fair has a lot of plastic and rubber machines around the exhibition. It is able to see the operation of ROMI’s “i4 cloud injection molding machine”, it can connect by internet, easy to expend and invest at the initial stage. All the funtions are managed by INTOUCH. I4 cloud is used to collect, analyze the data of factories and combined with industry 4.0. Then use the Internet and ERP software to connect multiple machines. Visit our platform and see more information of this K 2019!

2019 K Trade Fair Show Daily_6

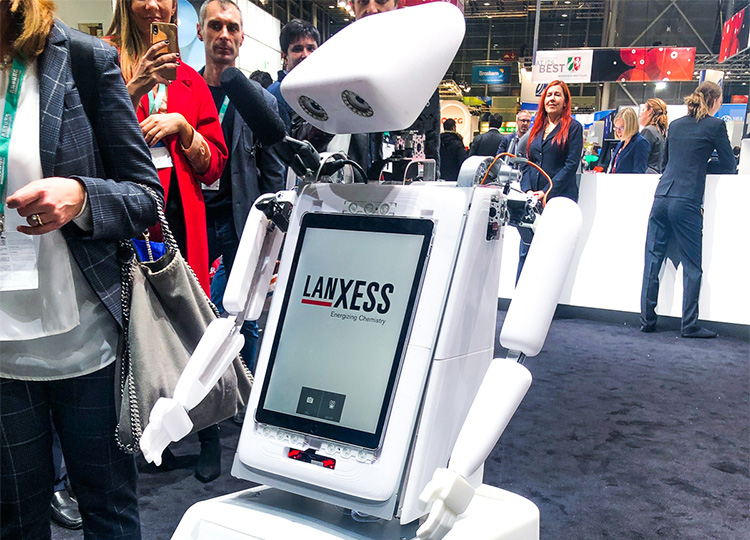

It was amazing when we arrived to Hall 6 of K Trade Fair. LANXESS's guide robot saw us and said “Hello” in Chinese to us. Moreover, the robot asked us to take a photo. We made a hand gesture "Vulcan salute" when taking pictures. Surprisingly, the robot said to us “You are also an alien!” LANXESS's guide robot is able to distinguish people's race, and reponse corresponding mother tongue. It truly made us marvel at the progress of AI.

2019 K Trade Fair Show Daily_7

TAITRA invited four Taiwan leading of rubber and plastic industry in-depth exploration how to response

industry 4.0.

"Taiwan rubber and plastic industry have been well prepared for the requirements of Industry 4.0 and

the necessary system integration" said by executive director of TAITRA

1. FCS Group - iMF4.0

2. Huarong Group - HFM

3. Multiplas - Smart Injection Molding Systems

4. Polystar - Multiple Integrated System

2019 K Trade Fair Show Daily_8

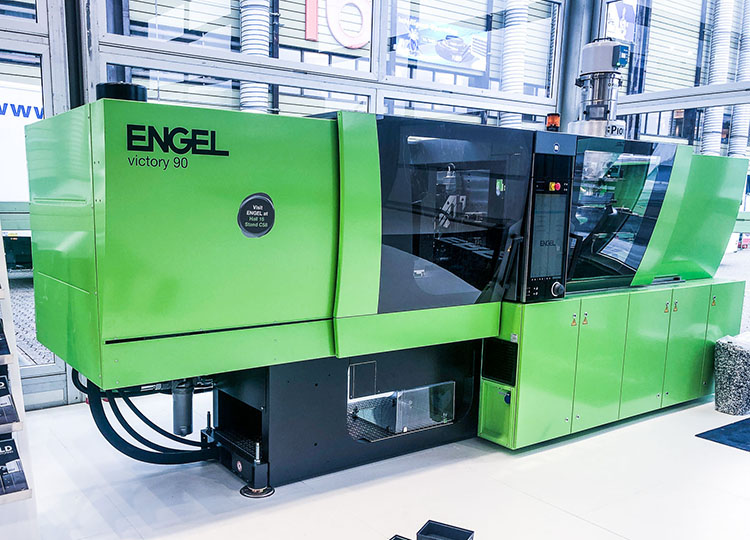

During K Fair 2019, ENGEL shows how Transport boxes will be produced by using the new skinmelt process. The transport boxes are particularly challenging for sandwich injection moulding due to their geometry. ENGEL nonetheless manages to achieve a high level of recycled content: over 50 %. And both the recycled and virgin material are polypropylene, ensuring that the sandwich-moulded products can also be easily recycled at the end of their service life. ENGEL has engineered an especially compact production solution based on an injection moulding machine: the second plasticising unit for the skin material is located at a sharp angle above the horizontal injection unit inside which the recycled material is melted - a highly space-saving design. Other stand-out features of the ENGEL solution are its easy-to-use visual display and the animation of the entire process on the injection moulding machine’s control unit. Excerpt from ENGEL website news.

Taiwan Exhibitors

Taiwan is the fifth largest producer of rubber and plastic machinery in the world and the fourth largest exporter. Has strong research and development capabilities, production standards and perfect after-sales service, so it is favored by global buyers.

FKI

The largest and finest machinery manufacturer in Taiwan Plastic Extrusion Industry. Established in 1953 by founder C.C Wei and spread its business to over 100 countries . FKI manufactures variety of plastic extrusion machinery...

- Hall 12, Stand No : F22

GEORDING

Specialize in plastic crushing, washing and drying line, turnkey plant for recycling plastic, rubber and plastic pelletizing, special composite materials pelletizing...

- Hall 12, Stand No : A52-41

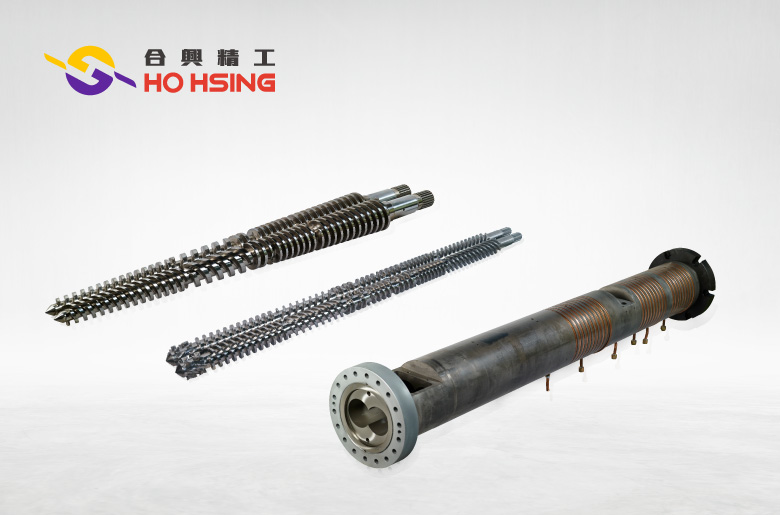

HO HSING

The professional manufacturer of twin screw and barrel in Taiwan. We approved ISO 9001 : 2000 international quality certification in 2005 and strictly ensured entire inspection from A to Z including raw material...

- Hall 12, Stand No : A52-41

GINDAI

We have sold worldwide over 40 countries. In the field of machine tool, plastics, semiconductor industry and centralized cooling system, GINDAI insists on innovative research and development...

- Hall 15, Stand No : C61

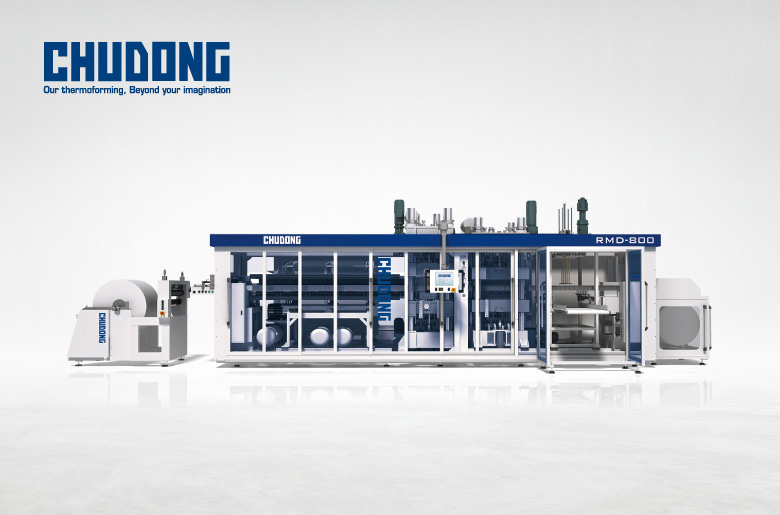

CHUDONG

Providing more diverse and flexible Plastic Thermoforming Machine, Pressure Forming Machine, Thermoforming Tool and Thermoforming System to satisfy the quantitative and ever-changing demands of the market...

- Hall 12, Stand No : A52-10

YEAR-CHANCE

Provide a good design for customers' various requirement, specializes in high pressure, high speed machines. Among high-pressure, high-speed machines has won widespread approval in the 3C industry...

- Hall 13, Stand No : D12-01

COSMO

COSMO is well-known for manufacturing plastic bag making machine with servo driving system, and producing about 300 sets per year of product...

- Hall 3, Stand No : F40

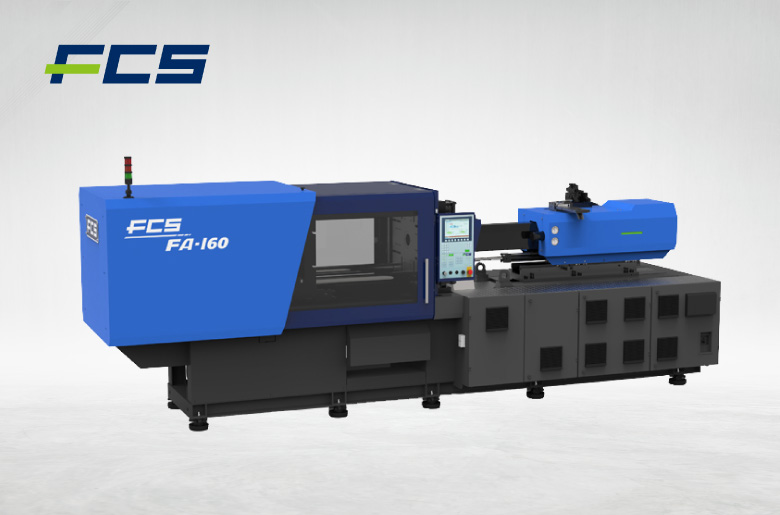

FCS

FCS Group, largest plastic injection molding machine manufacturers in Taiwan. Covering clamping force from 30 to 4,000 tons, injection volume from min 20 to max 120,000 grams.

- Hall 12, Stand No : B11

EVERPLAST

Everplast Machinery was specialized in manufacturing plastic extrusion machinery.For instance, pipes, profiles, soft pipes, door, compounding, WPC, and tooling...

- Hall 12, Stand No : A19

CYKF

We have a plentiful sales performance and are experienced in the automatic system of pelletizing for PVC, compounding and plastic recycling, and the automatic system of extrusion lines for pipe and profile...

- Hall 13, Stand No : D34

POLYSTAR

POLYSTAR has focused on user-friendliness of its machines through continuous re-engineering, making recycling extremely “Simple” for its users – Easy operation and maintenance...

- Hall 12, Stand No : B06

CHEN HSONG

Chen Hsong has grown from a small machinery workshop to one of the largest manufacturers of injection moulding machines in the world...

- Hall 13, Stand No : B43

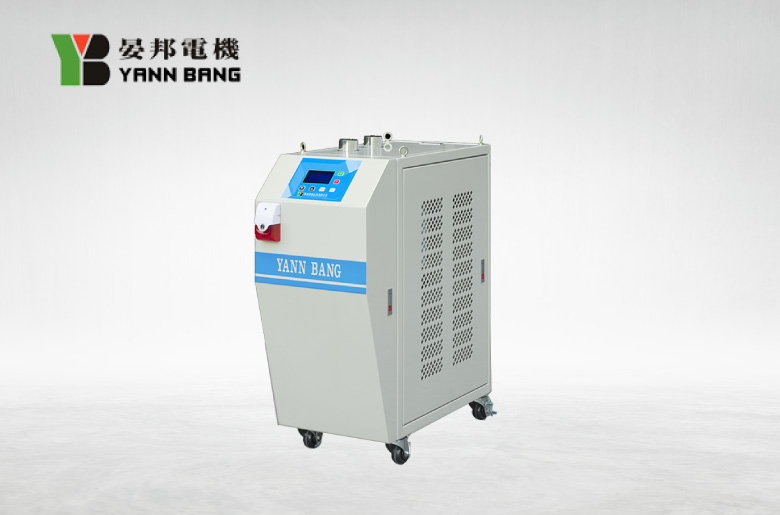

YANNBANG

YANN BANG, the specialist of automatic auxiliary conveying and drying system for plastic and rubber industry in Taiwan. Yann Bang have a completed products line and provide total solutions for you, such as drying system...

- Hall 12, Stand No : A52-24

GATEWAY

With over 30 years of manufacturing, engineering, tooling and plumbing experience. Gateway Corp. has earned the trust of our customers with our focus on quality, communication and reliability...

FLYING TIGER KJ

The Flying Tiger KJ was started by five experienced plastics molding experts and senior engineers who recognized that the production of quality plastic products requires precise temperature controls...

HENG CHIH

We specialize in granulating,recycling, dosing and mixing equipment. Slowly we branched out to a variety including drying and dehumidifying, feeding and conveying as well as heating and cooling...

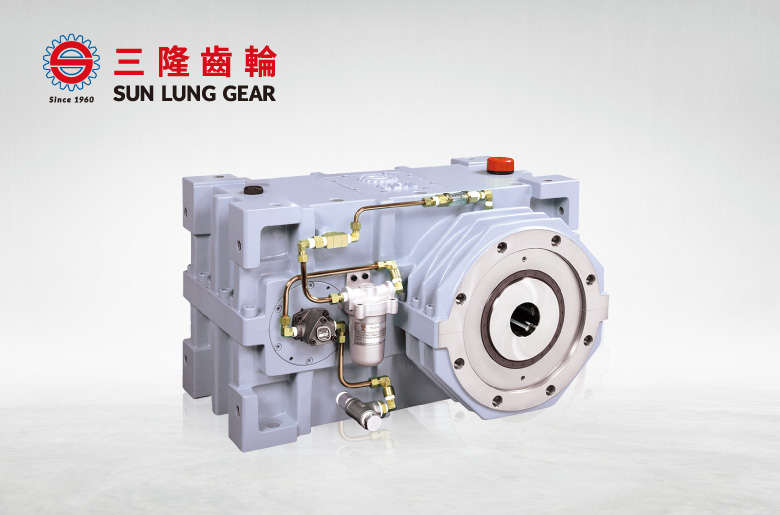

SUNLUNG

Specialized in designing and manufacturing precision gears and gearboxes for plastic extruders, plastic injection machines, blown molding...

RE-PLAST

Focus on manufacturing and marketing of pelletizing extruder and other auxiliary equipments for plastic compounding and recycling, and has always been committed to the development of the most simplified...